Are there any advantages to fiber optic cutting machines?

Release time:

2021-02-02 15:11

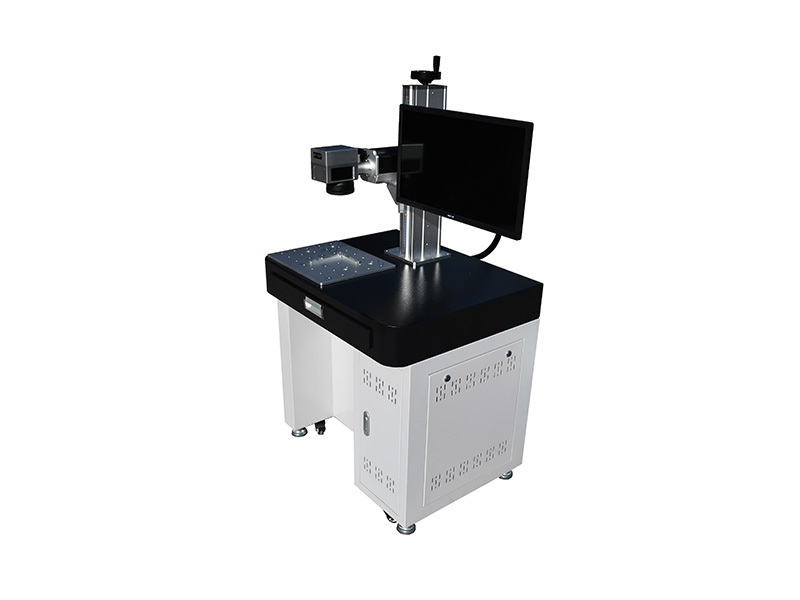

All cutting processes have their own advantages and disadvantages, but the advantages of fiber optic cleavers seem to stand out more than any other process. Fiber lasers have received much attention over the past few decades, but their advantages are quickly being realized among metal fabricators across the country. Fiber optic cutting machines can easily and smoothly adapt to a wide range of applications in various industries.

What are the advantages of fiber optic cutting machines?

Fiber cutting machines have several main advantages: the light propagated by optical fiber can block environmental interference very well, and the design of fiber laser is often very compact, with large gain bandwidth, large wavelength tuning range and the ability to generate ultra-short pulses. . It works effectively with high power and is suitable for a variety of cutting procedures.

Fiber lasers can cut thin materials very quickly and have the ability to cut reflective materials. They can also cut highly reflective metals such as copper, brass and aluminum without damaging the machine.

1. The object has no thermal damage

The laser emitted by the fiber cutting machine is very powerful, so it can easily cut thick materials such as steel. And they are so accurate that the beam causes no damage to surrounding materials. Many industries can benefit. Like the electronics industry, the beams in this industry need to work at very small sizes and cannot damage all the components these electronic devices need to function properly.

2. Outstanding performance

Fiber cleavers offer higher performance than many similar products, offering high levels of beam quality that can be highly focused and increase power density to achieve very high levels of accuracy. That means you can get your work done faster and with less power.

The main reason for using fiber laser cutting technology is to reduce the mechanical stress exerted on sheet metal parts during the cutting process. Lasers help eliminate impact stresses during cutting that can adversely affect sheet metal products. In addition, the heat-affected zone is very small and the rest is rarely heated, thus retaining the properties of the treated material.

Additionally, because laser cutting does not negatively impact sheet metal, the cost of intensive cutting of sheet metal can be kept low, allowing more parts to be manufactured per square meter of sheet metal.

In fiber optic cutting machines, complex cutting with good edge quality can be done accurately. Accurate fiber optic bundles can be used to create tolerant components in a fast, clean, and efficient manner that requires little operator intervention. High software and narrow cuts nest parts tightly, maximizing throughput and reducing material waste.