How to choose an optical fiber cutting machine? These five steps are indispensable

Release time:

2021-02-04 12:08

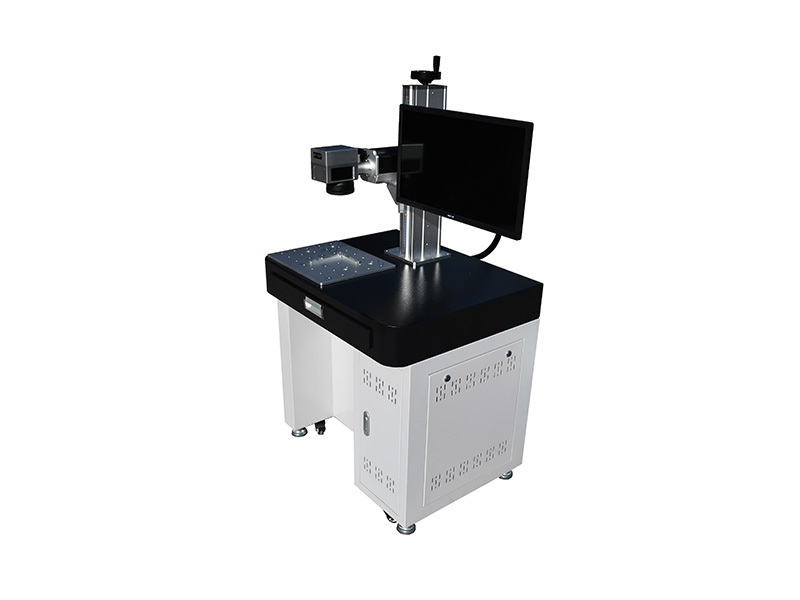

In recent years, fiber laser cutting technology has been widely used in sheet metal, handicrafts and other processing industries, and has become more and more widely used in the field of metal cutting or non-metal cutting. The technology of laser fiber cutting machines is quite mature and occupies a certain market share in the cutting industry. However, many users still have various problems in how to purchase a fiber cutting machine that suits them. So, how to choose a suitable fiber optic cutting machine? The five steps introduced by the editor below are indispensable!

1. Materials processed by the enterprise and scope of business needs

First of all, we must clearly consider the scope of our business, the thickness of the cutting material, the materials that need to be cut, etc. In the second step, you need to determine the power supply size and workbench size of the equipment you want to purchase. The power of fiber cutting machines currently on the market is between 500W and 6000W. The general size of the workbench can be customized according to customer needs.

2. Initial selection of suppliers

After confirming the demand, you can go to the market to purchase an optical fiber cutting machine. First, take a look at the performance and basic parameters of the machine. Select several companies with strength, price, and preferential prices in advance for communication and samples. Then we can conduct on-site inspections and conduct more detailed consultation on the machine's price, training, payment methods, after-sales service, etc.

3. Power size

When selecting the performance of laser fiber cutting machines, we must fully consider our own environment. The amount of power is very important. The cutting thickness determines the power of the laser tube. The greater the thickness, the greater the power of the laser tube selected, which is of great help to the company's cost control.

4. The core part of laser fiber cutting machine

Some important parts of the equipment also require great attention when we purchase them. In particular, the laser tube, cutting head, servo motor, guide rail, cooling system, etc. directly affect the cutting speed and accuracy.

5.After-sales service

The after-sales services of various manufacturers vary widely, and the warranty periods are also uneven. After-sales service must not only provide customers with effective daily maintenance plans, but also have professional mechanical and laser software training systems to help customers get started as soon as possible.

No matter how good the laser fiber cutting machine is, users will encounter various problems during use. When customers encounter problems that cannot be solved, it is particularly important for suppliers to provide timely solutions. These factors should be considered when purchasing a fiber optic cutting machine.