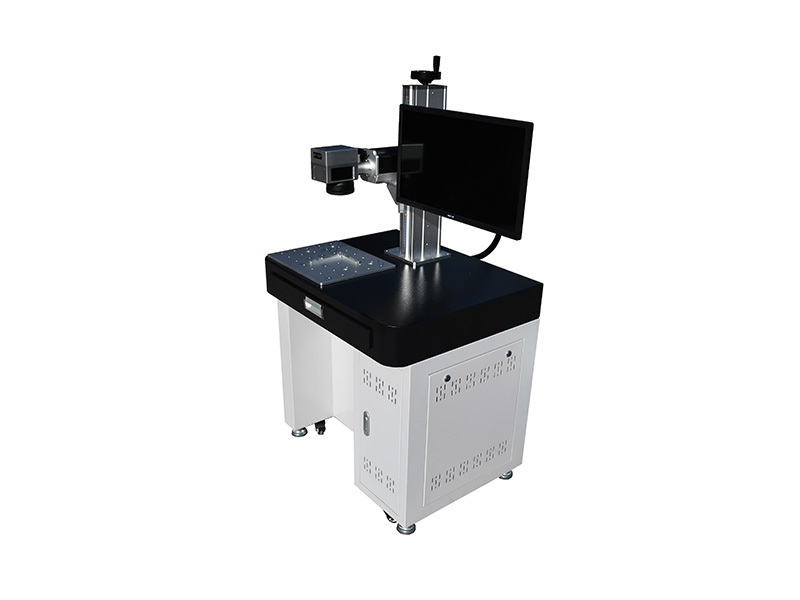

Laser cutting machine technology has broad development prospects and huge application space in the domestic market

Release time:

2021-02-03 12:10

The laser cutting machine condenses the laser light emitted by the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point. At the same time, the high-pressure gas of the melted or vaporized metal coaxially with the laser beam is blown. Walk. The power adding method of laser cutting machine has the characteristics of high precision and low power adding cost.

Laser cutting machine is realized by utilizing the high power density energy generated by laser beam. Under the control of the computer, the laser outputs controlled repetitive high-frequency pulse laser through pulse discharge, forming a beam with a certain frequency and pulse width. The pulsed laser beam is transmitted and reflected through the optical path, and is focused on the surface of the object through the lens to form a fine, high-energy-density light spot. The focal spot is located near the surface to be worked, and the material to be worked is melted or vaporized at high temperature instantly. Each high-energy laser pulse sputters a small hole in the surface of the object in an instant. Under the control of the computer, the laser processing head and the material to be processed perform continuous relative motion and dotting according to the pre-drawn graphics, thereby processing the object into the required shape. During the cutting process of the laser cutting machine, the light beam is condensed into a small focus through the lens of the cutting head, so that the focus reaches high power density, and the cutting head is fixed on the Z-axis. At this time, the heat input by the beam far exceeds the part of the heat reflected, conducted or diffused by the material, and the material is rapidly heated to the melting and vaporization temperature. At the same time, the high-speed airflow blows out the melted and evaporated material from the coaxial or non-coaxial side to form holes for cutting the material. With the relative movement between the focus and the material, the hole forms a continuous slit with a narrow width, and the material is cut. At present, the external optical path of laser cutting machines mainly adopts the flying optical path system. The beam emitted from the laser generator reaches the focusing lens on the cutting head through reflectors 1, 2 and 3, and forms a light spot on the surface of the material to be processed after being condensed. The reflector 1 is fixed on the body; the reflector 2 on the beam moves in the x direction as the beam moves; the mirror plate 3 on the z axis moves in the y direction as the z axis moves. During the cutting process, as the beam moves in the X direction and the Z axis moves in the Y direction, the length of the optical path keeps changing.

Compared with traditional cutting processes such as oxyacetylene and plasma, laser cutting machines have the advantages of fast cutting speed, narrow cutting slit, small heat-affected zone, good verticality, and smooth cutting edges. At the same time, there are many kinds of materials for laser cutting, including carbon steel, stainless steel, alloy steel, wood, plastic, rubber, cloth, stainless steel, ceramics, glass and composite materials. With the rapid development of market economy and science and technology, laser cutting technology has been widely used in automobiles, machinery, electricity, hardware, electrical appliances and other fields. Laser cutting technology has been developing rapidly in recent years, with an annual growth rate of 15 to 20 percent. Since 1985, China has been growing at an annual rate of nearly 25 percent. At present, the overall level of laser cutting technology in our country is still far behind that of advanced countries. Therefore, laser cutting technology has broad development prospects and huge application space in the domestic market.