The principle and development prospects of metal cutting machines

Release time:

2020-10-24 12:03

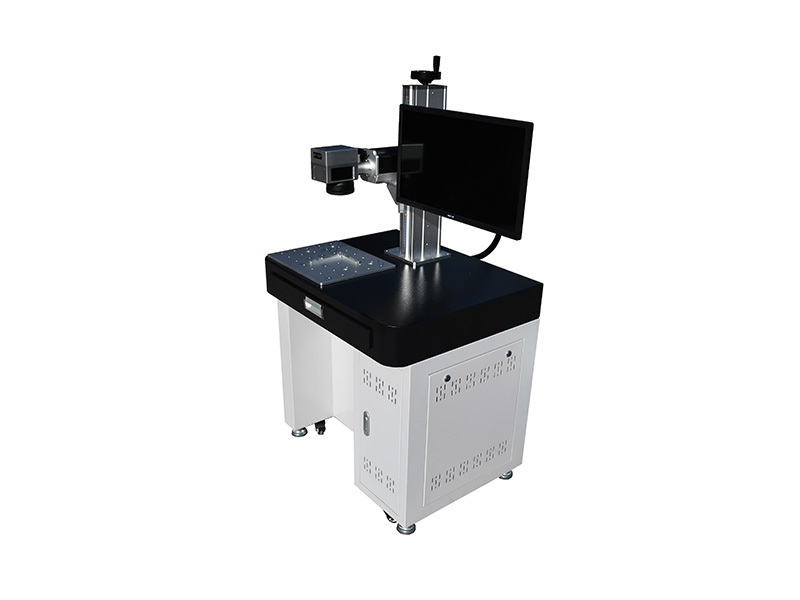

Laser is very magical. Currently, laser has been used in various industries, such as metal cutting, textile fabric cutting, laser marking, laser engraving, etc. But many people are not very clear about the principle of laser. Today, we will explain in detail how metal cutting machines work with lasers:

Laser beam principle: The laser beam is focused into a very small spot with a minimum diameter (less than 0.1mm), so that the focus reaches a high power density (greater than 106W/cm2). With the relative linear motion of the beam and the material, slits of narrow width (eg, approximately 0.1 mm) are continuously formed in the hole. The heat effect of trimming is small and almost no deformation of the workpiece occurs.

Cutting process: When laser metal cutting, add auxiliary gas suitable for the material to be cut. When cutting steel, oxygen should be used as an auxiliary gas to cause an exothermic chemical reaction with the molten metal, oxidize the material, and help blow away the slag in the gaps. In the metal processing industry, which plays a heavy role in industrial manufacturing, many metal materials can be cut without deformation regardless of their hardness (the thickness of industrial steel that can be cut by the most advanced metal laser cutting machine can be close to 20mm). Of course, for materials with high reflectivity, such as gold, silver, copper, aluminum alloys, etc., they are also good heat conductors, so laser cutting is difficult or even impossible (some difficult-to-cut materials can be cut with pulsed laser beams , the material's absorption coefficient of the beam will increase sharply due to the extremely high peak power of the pulse wave).

The development prospects of metal cutting machines:

As a new type of processing method, metal cutting machines have been widely used in the leather, textile and clothing industries due to their advantages of high precision, fast speed, simple operation and high degree of automation. Today, it is also widely used in metal processing. Compared with traditional cutting methods, metal cutting machines are not only cheap and low in energy consumption, but also because laser processing does not put mechanical pressure on the workpiece, the cutting product has good effects, high precision, fast cutting speed, safe operation and simple maintenance. . Laser equipment has been studied internationally for decades, but it is still at a new stage in China, especially metal cutting machines, which have many types but are still in the preliminary development stage.

Although the development of China's laser industry is preliminary, it has already made a leap under the guidance of international science and technology, and has performed outstandingly at a stage of higher quality than the same level. Since the birth and application of the first laser equipment in the 1960s, many experts in China have made efforts in the laser industry and made small achievements in the world. With the rapid development of the domestic economy, it has become a high-industry pillar of the laser market, with an annual growth rate of more than 20%. It has become a new starting point for the global laser market. According to expert predictions, the domestic laser market is still in a stage of rapid growth and can double in the future to maximize the expansion of the laser cutting equipment market and enable domestic high-end laser equipment to get out of the predicament and become a pillar of the international community. At present, the domestic laser industry is mainly concentrated in Shenzhen and Wuhan. Shenzhen is an important domestic sales market, leading other regions and has many years of development experience. Although the laser industry has made great progress and has been widely developed and applied, it still retains a certain space in scale, especially for metal cutting machines and precision welding in precision industries such as automobiles.

Previous article

Next article

Previous article

Next article