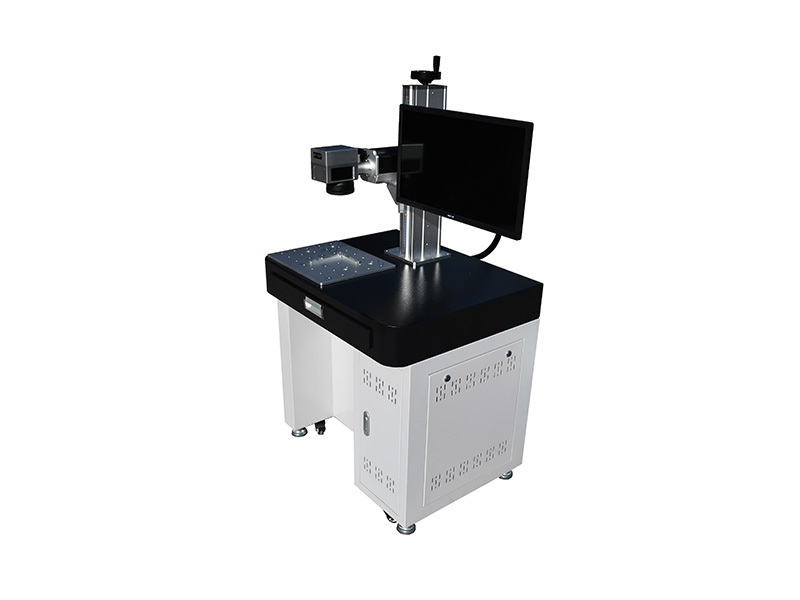

What are the uses of metal cutting machines?

Release time:

2020-10-27 12:03

1. Laser vaporization cutting

When metal cutting machines perform gasification cutting, they use high-energy-density laser beams to heat the workpiece, causing the temperature of the workpiece to rise rapidly. Within a short period of time, the substance reaches the boiling point and the substance begins to evaporate to form steam. These steams are injected at high speed to create cuts in the material. Since some materials require a high amount of heat to vaporize, the power required for laser vaporization by a metal cutting machine is very large. Vaporization cutting using laser is mainly used to cut extremely thin metal or non-metallic materials.

2. Laser melting cutting

When the metal cutting machine is laser melting, the metal material is heated and melted by the laser, and then sprayed through a nozzle coaxial with the beam to generate non-oxidizing gas (argon, helium, nitrogen, etc.). The liquid metal is discharged under the strong pressure of the gas to form a gap. . This type of fusion cutting does not require complete melting of the metal, but does require one-tenth of the melting capacity. Laser melting cutting method is mainly used to cut some active metals or non-oxidizing materials.

3. Laser oxygen cutting

The oxygen cutting principle of metal cutting machines is similar to oxyacetylene cutting. It uses laser as preheating heat source and oxygen as cutting gas. The cutting speed of laser oxygen method is much higher than laser vapor cutting and melting cutting. Laser oxygen cutting is mainly used to cut some easily oxidized materials.

4. Laser scribing and controlled fracture

The laser scribing of a metal cutting machine scans the surface of brittle materials with high energy density into small grooves, and then applies a certain amount of pressure, and the brittle material will crack along the small grooves. Q-switched lasers and CO2 lasers are commonly used for laser scribing. The local thermal stress generated by the laser grooved material is used to produce local thermal stress distribution in the material along the groove.

Laser cutting technology and other thermal cutting methods are essentially different from the mechanical processing of machine tools. Laser cutting machines concentrate light into a high-density beam. Laser cutting technology is different from other thermal cutting methods.

Compared with other thermal cutting methods, laser cutting technology has obvious advantages, such as fast cutting speed and high quality. Good cutting quality: The laser cutting spot is small, the energy density is high, the cutting speed is fast, and the cutting quality is good. The laser cutting hole is narrow, the dimensional accuracy of the cut parts can reach 0.05mm, the cutting surface is smooth and beautiful, and the surface roughness is only tens of microns. Even laser cutting can be used as the latter process. The slits can be welded without further processing and the parts can be used directly. After laser cutting, the width of the heat-affected zone is very small and has little impact on the performance of the material.

Previous article

Previous article