Technical means of laser welding machine

Release time:

2020-10-30 12:03

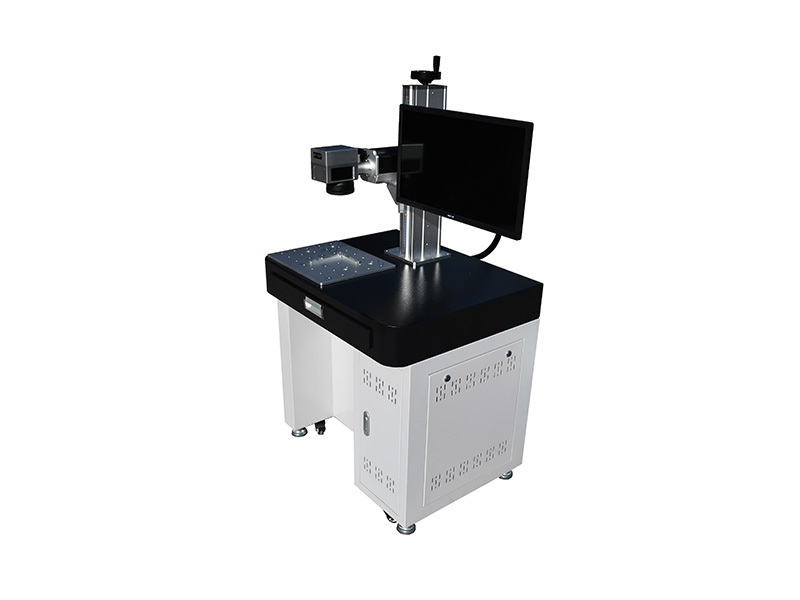

Laser welding machine is a machine for laser material processing, also known as laser welding machine and rust welding machine. According to their working methods, they can be divided into laser mold welding machines (manual welding machines, automatic laser welding machines, laser spot welding machines and optical fiber transmission laser welding machines).

Optical welding uses high-energy laser pulses to heat a small area of the material, and transfers the laser radiation energy to the welding purpose, so that the material melts to form a specific molten pool. The principle is similar to that of a laser welding machine. With the advancement of the times, laser welding technology is also constantly developing. Generally, filler wire laser welding does not use welding wire, but the assembly gap of the welded parts is very large, which is difficult to guarantee in actual production, limiting its application scope.

And laser welding of filler wire can greatly reduce assembly gap requirements. For example, for an aluminum alloy plate with a thickness of 2 mm, the plate gap must be zero to obtain a good forming effect. If 1.6mm thick welding wire is used as filler metal, a good weld can also be formed.

In addition, the filler wire of the laser welding machine can also adjust the chemical composition or perform multi-layer welding of thick plates. Laser beam rotation and laser welding can significantly reduce welding assembly and beam alignment requirements. For example, in a 2mm thick high-strength alloy steel plate butt joint, the allowable butt assembly gap increases from 0.14mm to 0.25mm, while for a 4mm thick plate, the allowable alignment error between the beam center and the weld center increases from 0.25mm 0.5mm.

Laser welding machines are also called laser cold welding machines, laser hydrogen welding machines, laser welding equipment, etc. According to their working methods, they can be divided into laser mold welding machines, manual laser welding equipment, welding machines, laser spot welding machines, and optical fiber transmission laser welding machines. , galvanometer welding machine, etc. Special laser welding equipment includes sensor welding machines and keyboard laser welding equipment.

Suitable for welding of integrated circuit leads, watch hairpins, electron gun components, sensors, high-power diodes (transistors, laptop casings, mobile phone batteries, electrical accessories, filters, stainless steel products, golf heads, etc.) and zinc alloy processing.

The working principle of the laser welding machine is to use high-energy laser pulses to heat a small area of the material. Laser radiant energy diffuses through heat transfer, guiding material to melt into a specific molten pool. Laser welding machines are mainly used for welding thin-walled materials and precision parts. Can realize spot welding, sealing welding, etc., with! Small weld width, small deformation, fast welding speed, no need or simple treatment of the weld after welding, no pores, precise control, high positioning accuracy, and easy automation.

Previous article

Next article

Previous article

Next article