Features of laser welding machine

Release time:

2020-11-02 12:03

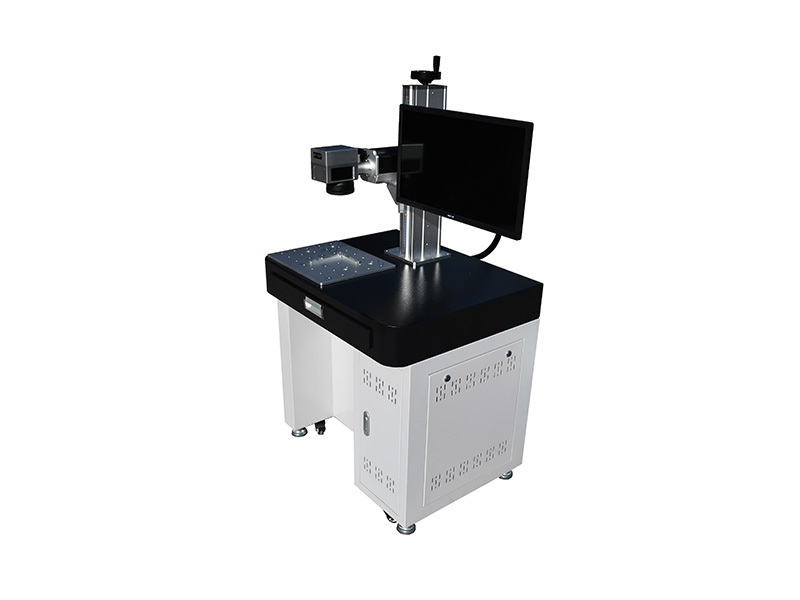

With the development of science and technology and the improvement of people's living standards, laser welding machines have appeared in recent years. And so what is a laser welding machine? What are the features and advantages of laser welding machines?

First, what is a laser? The world's first laser was produced in 1960, when ruby particles were excited by a flash lamp. Due to the thermal capacity of the crystal, it can only produce very short, low-frequency pulsed beams. Although the instantaneous pulse peak energy can be as high as 106 watts, reaching such a high value, it is still a low energy output.

Laser welding machine technology uses polarizers to reflect laser beams, which can be concentrated in a focusing device to produce a huge energy beam. If the focus is close to the workpiece, it will melt and evaporate within milliseconds. This effect can be used in the welding process.

The emergence of high-power CO2 lasers and YAG lasers has opened up a new field for laser welding. The key to laser welding machine equipment is high-power lasers. The wavelength of the laser is 1.06μm, and its main advantage is that it can transmit the beam through optical fiber, eliminating the need for a complex beam transmission system. Suitable for flexible manufacturing systems or remote processing, usually used for welding workpieces with high precision. The output power of the laser is 3~4kw, which is a commonly used laser in the automotive industry. The other is a gas laser welding machine, also known as a carbon dioxide laser.

Using molecular gas as the working medium, an infrared laser welding machine with a uniform size of 10.6 μm was developed. The laser welding machine can work continuously and output high power. Standard laser power is between 2-5 kilowatts. The main advantages of laser welding machines are as follows: fast speed and small deformation. Can be welded at room temperature or under special conditions.

Welding equipment is simple. For example, a laser beam can pass through a certain type of glass or gas in a vacuum, but not through air. three. It can be used for welding titanium, quartz and other refractory materials and dissimilar materials. After the laser is focused, the power density is higher. When welding high-power devices, the aspect ratio can reach 5:1 and up to 10:1. Micro welding is possible.

After focusing, the laser beam can obtain a very small spot and can be positioned accurately. Suitable for large-volume and small-volume welding production. It can weld inaccessible parts with great flexibility. Can be used for non-contact remote welding. Especially in recent years, with the application of optical fiber transmission technology in YAG laser processing technology, laser welding machine technology has been more widely promoted and applied.

Previous article

Next article

Previous article

Next article